Linear actuators are the driving force behind countless automation systems. Whether it’s positioning a solar panel, adjusting a conveyor belt, or moving a robotic arm, controlling the actuator precisely is what determines the success of the entire application. For anyone wondering how to control linear actuator setups effectively, it’s not just about wiring power, it’s about matching the control method to the performance demands.

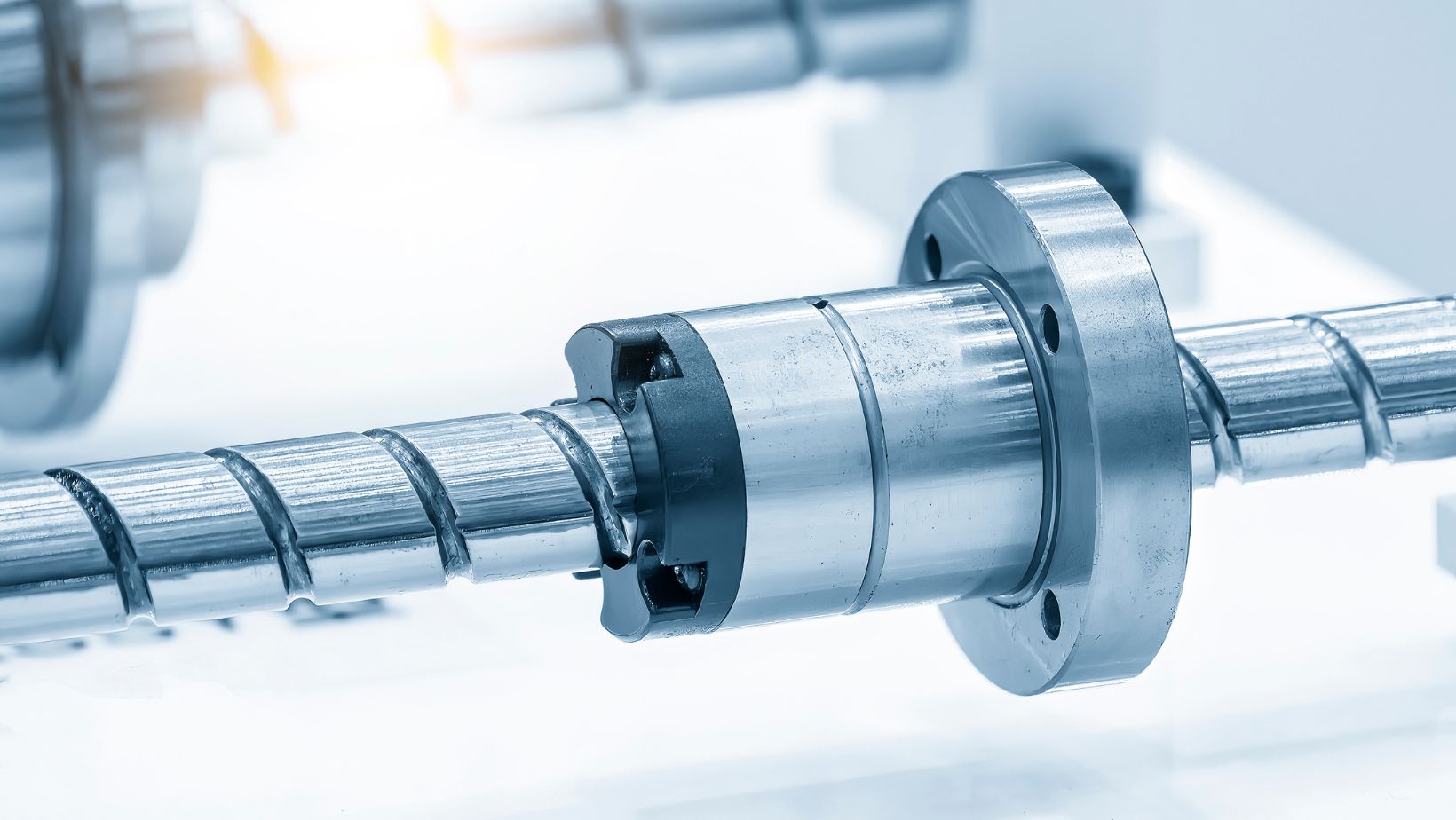

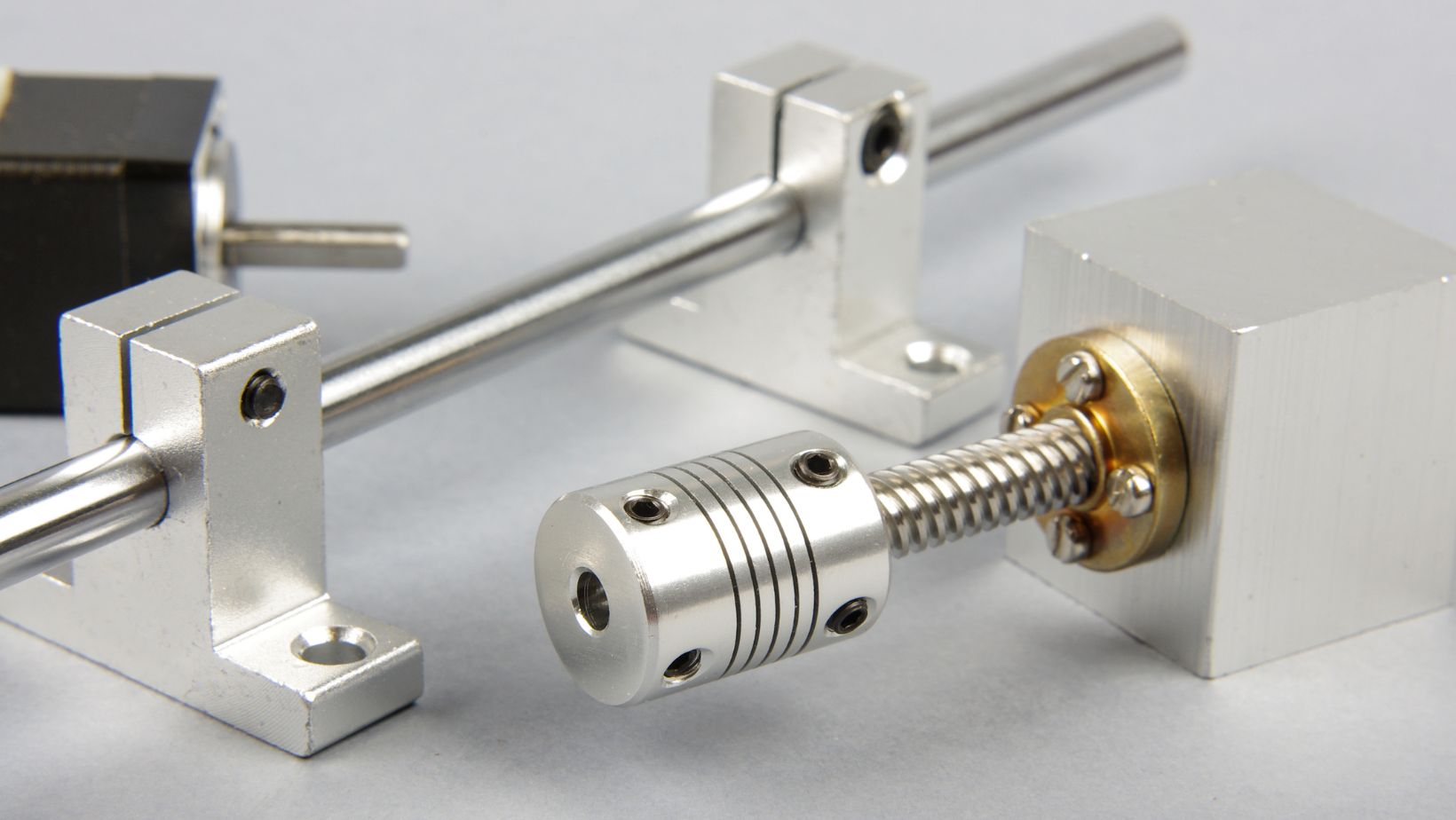

At its core, a linear actuator converts electrical energy into controlled linear motion. To command that motion, you need a control system that can tell the actuator when to start, stop, reverse, or hold position. The choice of control hardware depends on three main factors: voltage type (usually 12V or 24V DC), load requirements, and positional accuracy needed.

Basic Switching Control

The simplest approach uses a double-pole double-throw (DPDT) switch. This reverses polarity to extend or retract the actuator. While it’s inexpensive and straightforward, it offers only manual control with no automation. For example, in a height-adjustable workstation, an operator can press a switch until the desk reaches the desired height, then release it to stop.

Relay-Based Systems

When actuators are part of larger automated processes, relays allow them to be triggered by sensors, timers, or programmable logic controllers (PLCs). Imagine a ventilation hatch that opens automatically when a temperature sensor reaches a set threshold — the relay acts as the bridge between the sensor’s signal and the actuator’s motion.

Feedback Control for Precision

For projects requiring repeatable and accurate positioning, feedback is essential. Actuators equipped with Hall sensors or potentiometers send position data back to the controller. A microcontroller or PLC processes that data to make fine adjustments. This is common in robotics, where an arm must move to an exact point repeatedly without drifting.

PWM and Speed Control

Pulse-width modulation (PWM) allows the control system to adjust the actuator’s speed by varying the duty cycle of the supplied voltage. This technique is used in automated manufacturing equipment to slow down movement for delicate tasks and speed it up when less precision is needed.

Safety and Protection

Proper control also means protecting the actuator and connected systems. Limit switches stop travel at defined points, preventing over-extension or mechanical damage. Overcurrent protection ensures the actuator shuts off if it encounters an unexpected obstruction.

In practice, mastering actuator control means thinking about the bigger system — sensors, controllers, wiring, and mechanical design. Choosing the right approach balances precision, cost, and complexity. Whether it’s a single desk lift or a fully automated production line, the principles remain the same: deliver the exact movement, at the exact time, under the exact conditions required.

For engineers seeking deeper integration methods, the Guide by Progressive Automation offers wiring diagrams, control logic examples, and troubleshooting tips to take your actuator control to the next level.