Rare-Earth Metals and How We Get Them

The rare-earth elements are a set of 17 soft but dense metals. They span the 15 lanthanides, plus scandium and yttrium. Despite the name, these metals are actually abundant in the Earth’s crust. We didn’t know that when we named them, but they are very difficult to extract and refine, so they are still considered a scarce resource.

We get these elements, like any other metal, by mining them. However, they require a more delicate process than other mines that pull sturdy metals like iron or gold out of the ground. Most people know mine from their depiction in media, especially historical TV shows or online slot games set during the gold rush. Popular games like the Gold Rush Express slot portray nuggets and even whole bars of gold getting hauled out of a mountain by a gilded steam train, offering an exaggerated look back to a time when enthusiasm for mining was at an all-time high.

Previously, people would travel hundreds of miles just to get a peek at some precious metal. Now, that enthusiasm has turned to REEs, with some describing it as a gold rush in the making.

If it is a gold rush, it’s still in its earliest stages. While countries like China have been supplying rare-earth metals for some time, the US and Europe want to move away from dependency on their supply chains. To date, there is only one rare-earth element mine in the US – the Mountain Pass Rare Earth Mine and Processing Facility in California. It’s virtually guaranteed that more mines are coming to establish Western rare-earth supply chains and keep up with the boom in demand predicted by Future Market Insights. Electronics, electric vehicles, and clean energy all depend on these materials, so our reliance on them is only going to increase in the future.

How Laptops Depend on Rare-Earth Metals

While the exact manufacturing process differs, every modern mobile device uses rare-earth elements in some form. That includes laptops, but also smartphones, tablets, and any appliances that use magnets, speakers, and touchscreens. For laptops, the most commonly used REEs are neodymium, praseodymium, europium, and terbium.

Neodymium is used to create internal magnets used to spur the motors in hard drives. Neodymium is an old friend to computers because it was used to make permanent magnets that spur disc drives. Nowadays, it is also used to make high-performance speakers along with praseodymium. If your internet uses fiber-optic cables, then there’s a high likelihood they have been doped with praseodymium to amplify its signal.

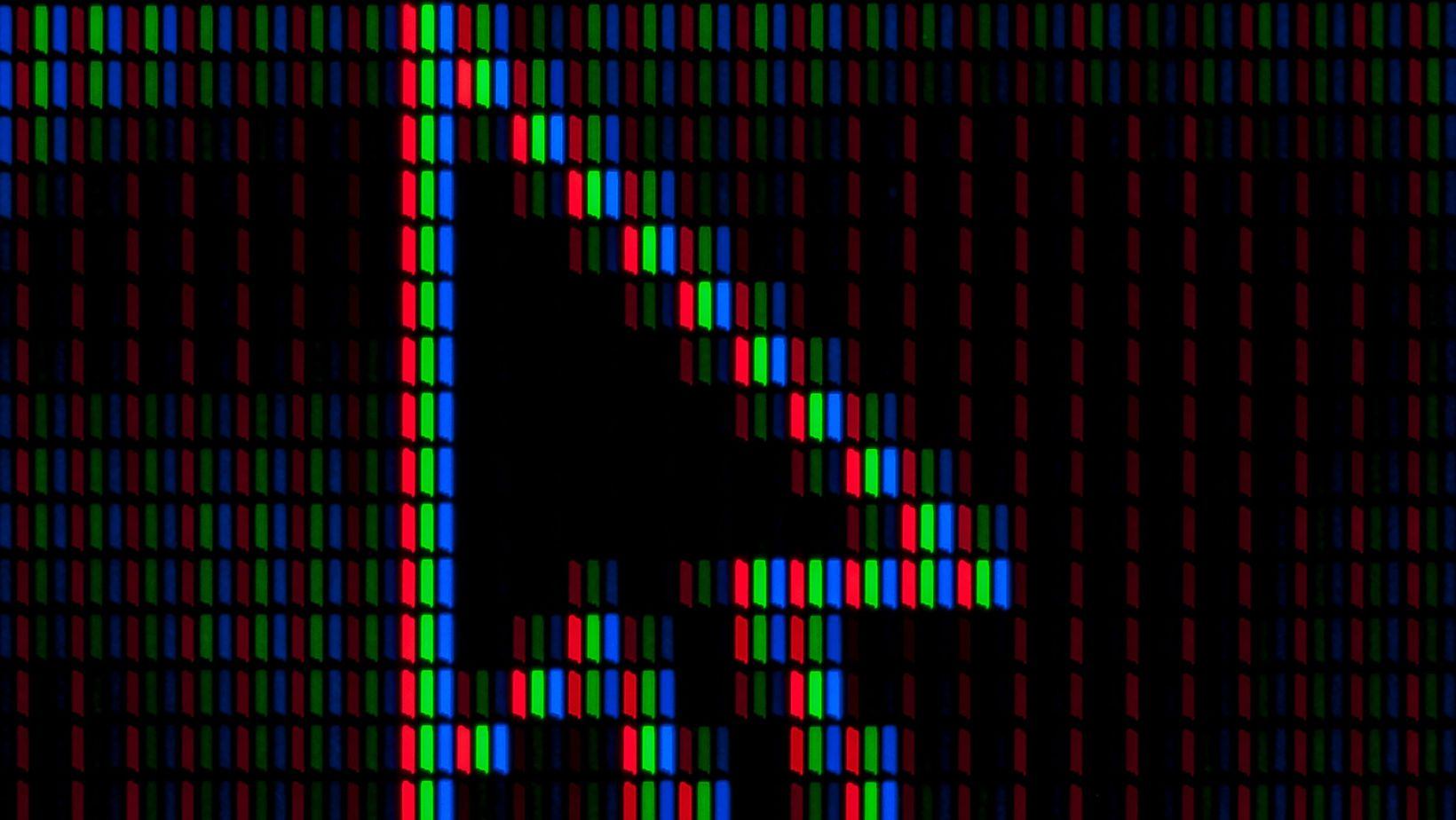

Europium and terbium are both used to make phosphors. Phosphor is a catch-all term for materials that emit light when power runs through them, so they have long been used to bring light to screens, from CRT TVs to modern laptops. If you’ve seen a pixel up close, those strips of red, green, and blue light are made from phosphors. Terbium is used for the green color, while europium is used for red, in conjunction with another REE – Yttrium. If you are curious, the blue color is created by zinc sulfide and silver (not REEs), but 2/3 of every LED pixel relies on rare-earth metals for their colors.

Those are the most prominent examples of rare-earth metals used in laptop manufacturing. As authorities like the Department of Energy pursue more REEs, they might find their way into other laptop parts in the future.

Alternatively, laptop hardware might advance beyond the need for them, but there will be no shortage of industries hungry for these valuable materials.